Products

Straight chains 400 series Plastic modular conveyor belts

Product Description

Modular belts are constructed with modules molded from thermoplastic materials connected with solid plastic rods. Except for narrow belts (one complete module or less in width),all are built with the joints betweenmodules staggered with those of adjacent rows in a “bricklayed” fashion. This structure can enhancetransverse strength and it is easy for maintain.

The total plastic and cleanable design can solve the steel belts easily polluted. Now the cleanable design makes the belts very suitable for food industry area as well. Also there are be widely used in many otherindustries,such as container making,pharmaceutical and automotive,lines of battery and so on.

Product parameters

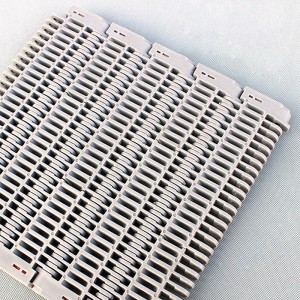

Raised Rib 400

Use with Finger Transfer Plates to virtually eliminate tipped at in-feed and discharge

Belt pitch:50.8mm

Open area:26%

Assembling method: connected with rods

|

Belt type |

Material |

Temperature range |

Working load(max.) |

Weight |

Backflex radius(min.) |

|

|

dry |

wet |

N/m(21℃) |

Kg/m2 |

mm |

||

|

Rib400 |

PP |

5 to 105 |

5 to 105 |

35000 |

9.52 |

50 |

|

PE |

-46 to +66 |

-46 to +66 |

26000 |

9.67 |

||

Raised Rib Base Flights 400

Belt pitch:50.8mm

Flights height:50/76/102/150mm

Flights fit belt series: Rib400

Side guards Series 400

Belt pitch: 50.8mm

Side guards height: 165mm

Side guards for belt series: Rib400

Finger Transfer Plates 400

Eliminates product transfer and tipping problems.

The fingers extend between the belt’s ribs allowing a smooth continuation of the product flow as the belt engages its sprockets.

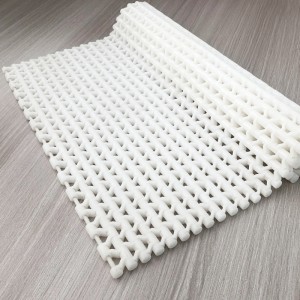

Flush Grid 400

Smooth upper surface, fully flush edges. Offers excellent lateral movement of containers

Belt pitch: 50.8mm

Open area: 17%

Assembling method: connected with rods

|

Belt type |

Material |

Temperature range |

Working load(max.) |

Weight |

Backflex radius(min.) |

|

|

dry |

wet |

N/m(21℃) |

Kg/m2 |

mm |

||

|

FG400 |

PP |

5 to 105 |

5 to 105 |

35000 |

8.89 |

50 |

|

PE |

-46 to +66 |

-46 to +66 |

26000 |

9.28 |

||

Classic sprockets, injection moulded – 400

For plastic belt: 400-Series.

|

Sprocket type |

Nr. of teeth |

Pitch diameter |

Outside diameter |

Bore |

|

H (mm) |

C (mm) |

DF (mm) |

||

|

1-400-6-40×40 |

6 |

101.6 |

91.4 |

□40×40 |

|

1-400-10-40×40 |

10 |

164.4 |

160.0 |

□40×40 |

|

1-400-10-50×50 |

□50×50 |

|||

|

1-400-10-60×60 |

□60×60 |

|||

|

1-400-12-40×40 |

12 |

196.3 |

195.6 |

□40×40 |

|

1-400-12-50×50 |

□50×50 |

|||

|

1-400-12-60×60 |

□60×60 |

Applications

Food Industry:

Meat (beef & pork), Poultry, Sea Food, Bakery, Snack Food (pretzels, potato chips, tortilla chips), Fruit & vegetables.

Non-food Industry:

Automotive, Tire manufacturing, Packaging, Printing/Paper, Postal, Corrugates cardboard, Can manufacturing, PET manufacturing and Textile.

Large production base, covering an area of 20000 square meters, standardized production and operation mode, timely delivery, low price and good quality

Certificate

Our company has passed FDA certification and ISO9001 quality management system certification, and has more than 200 patents.

Q&A

Q: Are you a trading company or manufacturer?

A: We are a manufacturer of modular belt, chains belt and conveyor components, with head office in Nantong, Jiangsu, China

Q: How long is the delivery time?

A: Generally 5-7 working days. It depends on the quantity.

Q: Do you provide samples?

A: Yes, samples are available.

Q: How can I place an order? What is the whole process?

A:1. Firstly, send us your detailed requirements(belt types, sizes, applications)by Email, Cantonfair Website, etc.

2. Then we will provide our best solution and quotation as per your requirements.(Samples available for testing if necessary.)

3. Once order confirmed and payment done, we will arrange production immediately.

4. Finally, goods will be send by sea/air/express etc.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.