Products

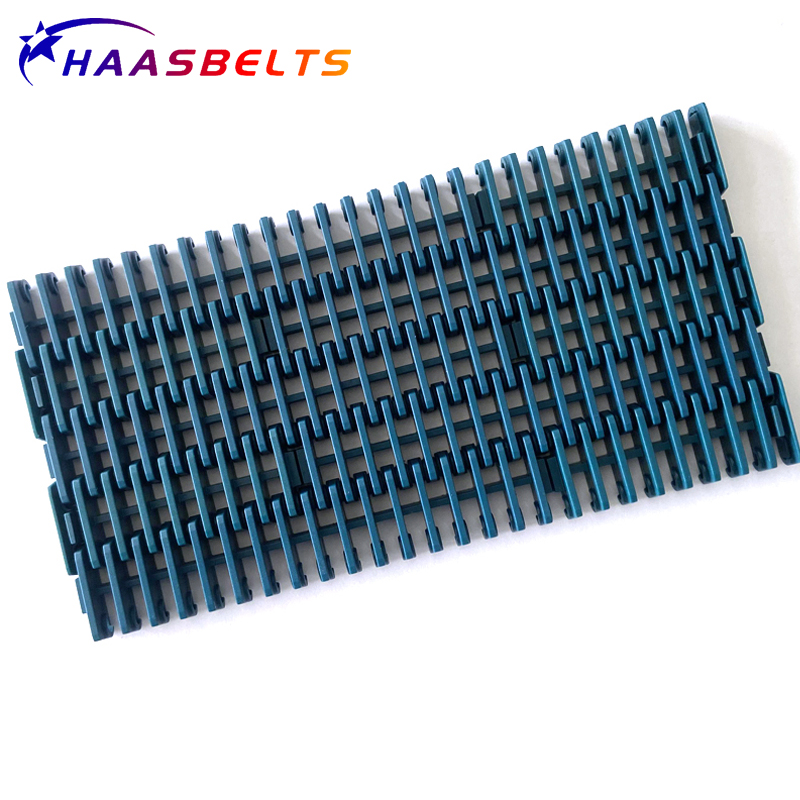

HAASBELTS Conveyor Raised Rib 1000 Series Plastic Modular Belt

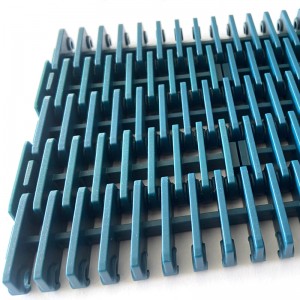

The protruding rib mesh belt is a specially designed plastic mesh belt, which adds a protruding rib structure on the basis of the traditional flat plastic mesh belt. These protruding rib structures usually present a V-shape or U-shape and can be arranged along the width direction of the mesh belt. The advantages and application fields of protruding rib mesh belts will be introduced below.

First of all, the protruding rib structure of the protruding rib mesh belt increases the friction on its surface. It can hold the material more firmly to prevent the material from slipping, leaking or dumping during conveying. This design feature makes it especially suitable for applications with inclined surfaces or where enhanced material retention is required.

Secondly, the protruding rib structure of the protruding rib mesh belt can provide better support and stability. This is especially important when conveying heavy materials or materials with irregular shapes. The ribbed structure can effectively support the material, prevent it from deformation or accumulation, and ensure smooth conveying.

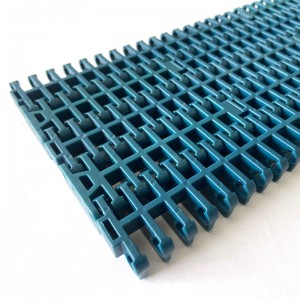

Third, the protruding rib mesh belt also has good air permeability. Due to the existence of the rib structure, the contact area between the material and the mesh belt is reduced, thereby reducing the resistance to the passage of gas and liquid. Therefore, protruding rib mesh belts are often used in applications that require ventilation or liquid drainage, such as wastewater treatment, food processing, etc.

Finally, the protruding rib mesh belt is made of plastic, which has the advantages of light weight, wear resistance and corrosion resistance. It is not easy to rust, corrode, easy to clean and maintain, suitable for many industrial environments.

All in all, the protruding rib mesh belt provides better material fixation, support and stability through the protruding rib structure, and is suitable for various application scenarios that require enhanced material retention and control. Its benefits include increased friction, support and stability, good breathability, and the excellent properties of plastic materials. Ribbed mesh belts are playing an increasingly important role in material conveying and are widely used in many industries.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.

-1-300x300.jpg)