Products

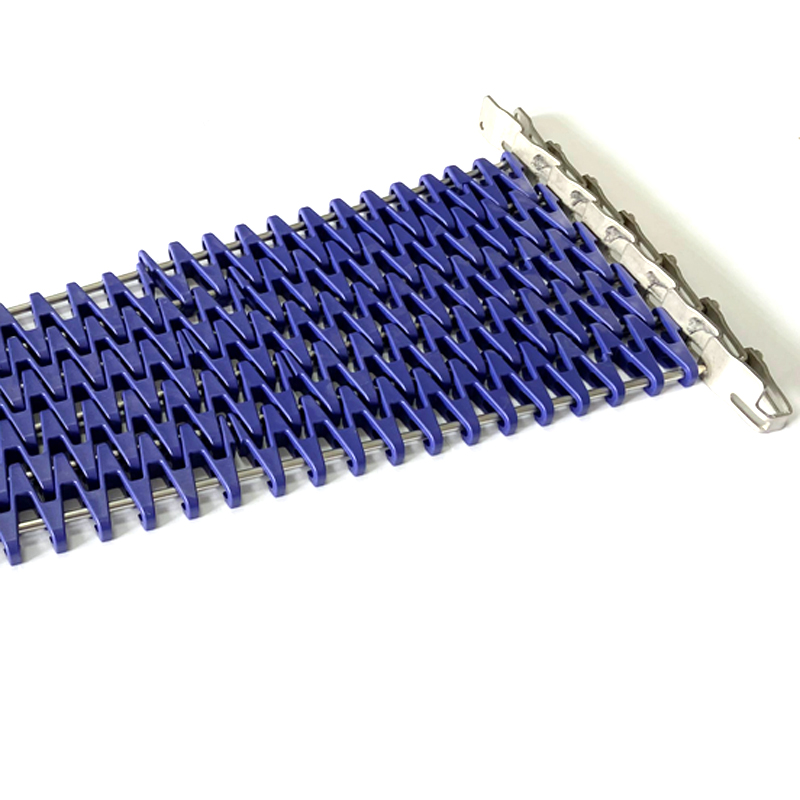

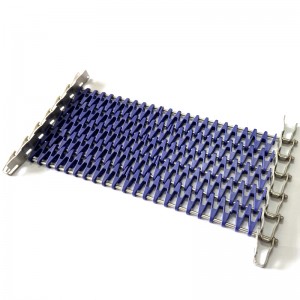

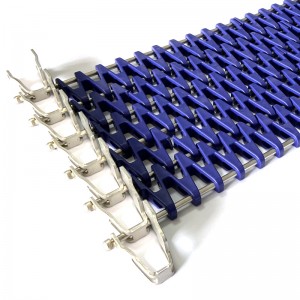

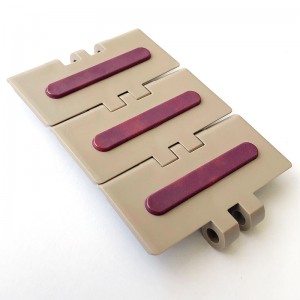

HAASBELTS Conveyor U193 Spiralox Flush Grid

Sprocket parameters

|

Sprocket type |

Number of teeth |

Pitch diameter |

Outside diameter |

A1 |

Bore |

|

H (mm) |

C (mm) |

mm |

DF (mm) |

||

|

1-U193-17-40R |

17 |

207.4 |

215.8 |

98.0 |

φ40 |

|

1-U193-17-50R |

φ50 |

||||

|

1-U193-17-60R |

φ60 |

Maintenance and upkeep of spiral mesh belt conveyor

Regular inspection: Regularly inspect all components of the spiral mesh belt conveyor, including bearings, chains, mesh belts, etc., to check for wear, looseness, or malfunctions. Especially for mesh belts, impurities attached to them should be regularly cleaned to avoid affecting their normal operation.

Lubrication: Regularly lubricate the bearings and chains of the spiral mesh belt conveyor to reduce friction and wear. For bearings, lubricating grease can be added regularly, and the total amount of injection can refer to 2/3 of the internal space of the bearing box; Soak the suspension bearings and shafts in lubricating grease every 4 intervals.

Cleaning: Keep the spiral mesh belt conveyor clean to prevent impurities and dirt from entering. During the conveying process, large objects or metal objects in the material should be avoided from entering the conveyor to avoid damage to the equipment.

Tightening: Regularly check the tightening of various components of the spiral mesh belt conveyor, and tighten them in a timely manner if any looseness is found.

Maintenance of drive device: Regular maintenance of the drive device of the spiral mesh belt conveyor, including checking the operation of the drive motor and reducer, as well as checking the tension and lubrication of the drive chain.

Shutdown maintenance: After a long shutdown, it is necessary to run the machine without load for a period of time to ensure that all components are functioning properly before carrying out load operation. Before stopping the machine, all materials inside the conveyor should be conveyed to avoid damage caused by materials being left in the conveyor for a long time.

Preventive maintenance: Develop a regular preventive maintenance plan, including regular inspections, lubrication, cleaning, etc., to prevent equipment failures from occurring. If any abnormal sound or vibration is found in the equipment, it should be stopped immediately for inspection and troubleshooting.

By following the maintenance steps above, the service life and performance of the spiral mesh belt conveyor can be effectively improved, and the occurrence of faults can be reduced.

The process of customizing modular plastic mesh belts

Develop and design detailed production plans based on customer needs and specific equipment requirements.

Make molds, select suitable plastic materials, and inject plastic modules through matching injection molding machines.

Splice according to the customer's width and length to form a modular plastic mesh belt.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.